April 1, 2025

EPLAN Electrical Design & Integration: Comprehensive Solutions from Concept to Installation

The Power of EPLAN Electric P8 for Industrial

Our company specialises in comprehensive EPLAN electrical design services that guide your automation projects from initial concept through final installation. Using EPLAN Electric P8 – the industry-leading electrical CAD platform – we deliver high-quality schematics, control panel layouts, and detailed documentation that ensure your projects are executed smoothly and efficiently.

EPLAN Electric P8 stands as one of the world’s premier software solutions for electrical engineering and automation design. This fully integrated ECAD platform enables engineers to plan, design, and document electrical systems for machines and plant installations with unprecedented speed and accuracy. Unlike traditional CAD tools, EPLAN offers virtually unlimited possibilities for project planning, documentation, and management of automation projects.

With EPLAN, we can automatically generate detailed reports like bills of materials, wiring lists, and device lists directly from your schematics. This means that as we create electrical drawings, the software simultaneously builds the data needed for manufacturing and assembly, ensuring nothing is missed in the process.

Key EPLAN Capabilities That Enhance Your Projects

EPLAN is more than just a drawing tool – it’s a comprehensive platform of integrated engineering solutions. The EPLAN platform connects various modules so digital data flows seamlessly from one stage to the next, getting enriched at every step. Some of the key capabilities include:

- Automatic cross-referencing of components and wires across pages

- Built-in symbol libraries supporting multiple standards (IEC, ANSI/NFPA, etc.)

- Real-time error checking to catch issues before they become problems

- Parts database linking each component to manufacturer data

- 3D cabinet layout with EPLAN Pro Panel for creating digital twins of control panels

- Multi-language and standards support for global projects

With these powerful features, EPLAN provides a centralised, data-driven approach to electrical design – you concentrate on the engineering, and the software ensures consistency and completeness of the project data in the background.

Solving Common Electrical Design Challenges

By adopting EPLAN Electric P8 as our design environment, we help clients overcome common challenges that plague electrical engineering projects:

Preventing Design Errors

Manual drafting or using generic CAD tools often leads to wiring mistakes, forgotten connections, or mismatched device ratings. EPLAN dramatically reduces such errors through automated consistency checks and intelligent design rules. Its advanced tools for schematics (like automatic wire numbering and device tagging) improve design accuracy and catch issues early, minimising implementation errors.

Eliminating Documentation Inconsistencies

Keeping schematics, cable schedules, terminal diagrams, and BOMs in sync is difficult when done manually. With EPLAN, a single source of truth drives all project data – schematics, lists, and panel layouts are all linked. Any design change is automatically reflected everywhere, ensuring documentation consistency without tedious manual edits.

Optimising Panel Layout & Wiring Design

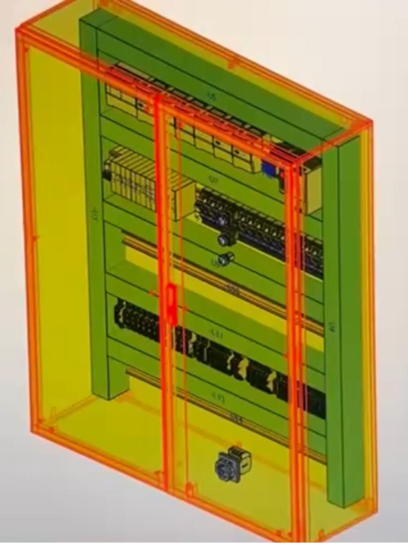

EPLAN’s integrated panel layout module (Pro Panel) uses schematic data to build a 3D digital model of the enclosure. This means by the time we finish the electrical design, we also have a virtual cabinet complete with exact component placements, wire routing paths, and even cable lengths. The software will flag issues like components placed too close together or not meeting clearance requirements, catching problems at the design stage rather than during building.

Improving Traceability and Project Transparency

EPLAN eliminates traceability issues by automatically cross-referencing every connection and device throughout the project. Each wire jump, contact, and PLC I/O is linked, with navigation tools that let you jump between references instantly. This means from any device on a diagram, you can find all occurrences and related components with a click, ensuring nothing gets “lost” in the pages.

Our End-to-End Design Process

We offer a complete solution for electrical design, taking your project through every phase from initial concept to installation and commissioning:

1. Concept Development & Pre-Planning

We work with you to define requirements and initial system architecture. Using tools like EPLAN Preplanning, we capture early engineering data to lay out the project scope, helping to generate initial specifications or data sheets for approval and budgeting.

2. Detailed Schematic Design

Our engineers develop detailed electrical schematics using EPLAN Electric P8. This includes multi-line wiring diagrams, control circuit schematics, PLC I/O drawings, and single-line power distribution drawings as needed. EPLAN allows us to design these schematics efficiently with standardised symbols and reusable macro circuits.

3. Component Selection & Parts Integration

We handle component selection and integration of part data. EPLAN’s vast component database provides access to thousands of parts – from circuit breakers and contactors to PLC modules – complete with technical data, symbols, and 3D models. Each component in the drawings is linked to a part number and data sheet, ensuring an accurate Bill of Materials.

4. Wiring Diagrams & Terminal Plans

EPLAN automatically generates connection lists and wiring tables, which we refine into clear wiring diagrams and terminal connection plans. Every wire is assigned a number or label per your preferences, and terminal strips are laid out showing which wires go where. All cables, ferrules, and termination details are documented for precise installation guidance.

5. Control Panel Layout & Enclosure Design

We provide full control cabinet layout using EPLAN Pro Panel for 3D or 2D panel layout tools. We take the electrical design and arrange all devices within the control panel or MCC enclosures, creating panel layout drawings showing the exact placement of every device – PLC racks, power supplies, relays, wiring ducts, and cable trunking.

6. Bill of Materials & Procurement Data

Once the design and layouts are complete, we generate the Bill of Materials and other procurement lists directly from the EPLAN project. These reports are extremely accurate since they are pulled from the live design data, not by counting items manually. We provide a structured BOM organised by categories to simplify ordering.

7. Installation, Testing & Documentation

Our support continues through installation and commissioning. We produce all the final documentation needed for assembly and wiring installation, including numbered wiring diagrams, cable routing layouts, assembly drawings, and an installation manual if required. During on-site installation, this level of documentation greatly reduces errors and questions.

Benefits of EPLAN-Based Design for Your Business

Using EPLAN for electrical design delivers tangible benefits for companies in manufacturing, process industries, and automation:

Reduced Engineering Time and Costs

EPLAN’s automation capabilities allow us to complete design projects faster and with less effort than traditional methods. Routine tasks like drawing wire connections, generating reports, or renumbering components are done automatically, freeing up engineering time. Studies have shown productivity can increase dramatically – in some cases by up to 70%.

Improved Documentation & Maintainability

High-quality, standardised documentation is a hallmark of an EPLAN project. Every wire, terminal, and component is clearly identified and cross-referenced, making schematics and panel layouts much easier to understand and follow. This pays dividends throughout the asset’s life – maintenance technicians find it straightforward to navigate drawings, trace circuits, and locate components during service or troubleshooting.

Future Scalability and Reuse

EPLAN encourages a modular design approach – creating circuit macros for common functions (motor starters, sensor circuits, VFD drives, etc.) that can be reused and adapted. If your manufacturing line needs to scale up or add new units, we can quickly replicate and modify the existing EPLAN project rather than redrawing everything.

Reduced Commissioning Errors and Downtime

Because the design has been rigorously checked and documented, assembly and wiring tend to be correct the first time. Many potential errors are eliminated at the design stage, translating to fewer mistakes on-site during commissioning. This results in shorter commissioning time, reduced risk of costly delays or rework, and a faster ramp-up to production.

Compliance and Quality Assurance

EPLAN helps ensure industry standards and safety requirements are rigorously followed. The software comes with libraries of standard-compliant symbols (for IEC, ISO, NFPA/UL, etc.) and formats. From CE markings to UL panel requirements, an EPLAN project can be tailored to comply, providing a clear paper trail for quality assurance.

Our EPLAN Design & Integration Services

Our team combines EPLAN software expertise with practical knowledge of electrical engineering and installation. We offer these key services:

Complete Project Design in EPLAN

We undertake complete electrical project design from scratch using EPLAN Electric P8 and its associated tools. We handle everything including I/O lists, cable schedules, loop diagrams, and integration of client-specific standards, maintaining a single unified EPLAN project that ties it all together.

Revising & Updating Outdated Drawings

We convert and update legacy drawings into EPLAN, breathing new life into your documentation. During this process, we improve and standardise them – replacing outdated symbols with standard ones, correcting mistakes, and inputting device data into the EPLAN parts database. The result is a clean set of digitised schematics in EPLAN that reflect your current system accurately.

Standardising Design Libraries & Templates

Using EPLAN’s powerful macro and library features, we develop standard circuit templates and device libraries tailored to your business. These libraries ensure every new project uses the same symbols, tag naming conventions, and wiring styles, improving consistency across your projects and reducing design time and errors.

Ensuring Compliance with Safety and IEC Standards

We ensure designs adhere to relevant standards from the start, including IEC 60204 (machine safety wiring), NFPA 79 (industrial machinery), UL panel requirements, and CE marking directives. We select correctly rated components, implement required safety circuits per ISO/IEC guidelines, and use standard symbols and colour codes.

On-Site Support and Electrical Installation

Our job doesn’t stop at delivering drawings. We support on-site electrical installation and commissioning to ensure implementation matches the design. We utilise tools like EPLAN eVIEW and Smart Wiring to enhance collaboration during build and commissioning, providing installers with digital wiring lists that reduce misunderstandings.

Why Choose EPLAN over Other Electrical CAD Tools?

EPLAN offers several advantages over other electrical drafting tools such as AutoCAD® Electrical or generic CAD software:

Purpose-Built for Industrial Automation

Unlike general CAD programs, EPLAN is specifically designed for electrical engineering tasks. It treats the electrical project as a connected whole, not just a collection of separate drawings. This database-driven approach ensures all project information is stored centrally and consistently.

Advanced Automation and Features

EPLAN comes with advanced features that streamline the engineering process – automatic cross-references, one-click generation of terminal diagrams and cable lists, and smart error-checking. By automating repetitive tasks and ensuring consistency, EPLAN allows engineers to accomplish in minutes what might take hours in a more manual CAD environment.

Integrated 3D Panel Design

With EPLAN Pro Panel, the same software that creates your schematic also produces a 3D layout of your control cabinet. This integration yields multiple advantages: accurate wire length calculations, automated drilling templates, collision checks, and even NC data for wiring and cutting machines, all derived from the design.

Comprehensive Documentation & Reporting

EPLAN inherently produces a complete set of documents needed for an electrical project at the push of a button – wiring lists, from/to connection diagrams, cable pull lists, bill of materials, terminal strip layouts, and PLC I/O maps. Once the design is done, you can trust that all the documentation is done as well.

International Standards and Widespread Adoption

EPLAN is a globally recognised tool, widely adopted especially in Europe and increasingly in North America and Asia. The software’s strong support for IEC standards and multi-language documentation makes it ideal for projects that span countries and continents.

Choose Our EPLAN Expertise for Your Next Project

By choosing our company for your electrical design needs, you gain access to our deep experience with EPLAN and our commitment to engineering excellence. Whether you need a small schematic revision or a large greenfield project, we apply the same rigorous approach and attention to detail.

We deliver EPLAN designs that installers trust, that inspectors approve, and that maintenance personnel find easy to work with – a complete solution from concept to installation. Contact us today to discuss how our EPLAN electrical design and integration services can help your next automation project succeed.