Comprehensive electrical design services from concept to installation using industry-leading EPLAN Electric P8 platform.

Our EPLAN Expertise

At Sull Systems, we specialise in comprehensive electrical design and documentation using EPLAN Electric P8 – the industry-leading electrical CAD platform. Our services cover every stage of your project, from initial concept through detailed design to final installation and documentation.

What is EPLAN Electric P8?

EPLAN Electric P8 is a fully integrated ECAD (Electrical Computer-Aided Design) platform that allows engineers to plan, design, and document electrical systems for machines and plant installations with speed and accuracy.

Unlike basic CAD software, EPLAN provides a centralised, data-driven approach to electrical design – you concentrate on the engineering, and the software ensures consistency and completeness of the project data in the background.

Key Capabilities

Automated cross-referencing of components and wires

Integrated schematic design and panel layout

Automatic generation of documentation (BOMs, wiring lists, etc.)

Comprehensive parts database with manufacturer data

Real-time error checking during design

3D cabinet layout with EPLAN Pro Panel

Multi-language and standards support (IEC, NFPA, etc.)

Our EPLAN Design Integration Services

Complete Project Design

We undertake complete electrical project design from scratch using EPLAN Electric P8 and its associated tools. Our team handles everything including:

Complete documentation packages

Schematic design to industry standards

Power distribution and control circuit design

PLC I/O allocation and documentation

Instrument loop diagrams

Cable and wiring schedules

Legacy Drawing Conversion

We convert and update existing documentation into modern EPLAN format:

Migration from AutoCAD, legacy CAD, or paper drawings

Standardisation of symbols and formats

Error correction and documentation improvement

Enrichment with manufacturer part data

Conversion to modern safety standards

Creation of searchable, maintainable documentation

Library & Template Development

We create standardised components and templates for your organisation:

Custom circuit macros for frequent designs

Company-specific symbol libraries

Standardised title blocks and page layouts

Reusable project templates

Component database with your preferred parts

Documentation standards and formats

Control Panel Layout & Design

Using EPLAN Pro Panel, we create detailed 3D layouts of your control cabinets and enclosures:

Accurate 3D positioning of all components

Thermal design and load calculations

DIN rail and cable duct layouts

Wire routing optimisation

Collision detection and clearance checks

Manufacturing data for drilling and assembly

Standards Compliance

We ensure your designs meet industry regulations and standards:

NFPA 79 (industrial machinery)

UL panel certification requirements

CE marking directives

Industry-specific standards (ATEX, FDA, etc.)

Company-specific standards and convention

IEC 60204 (machine safety wiring)

On-Site Installation Support

We don’t just deliver drawings – we provide ongoing support during implementation:

Final as-built documentation

Collaboration with panel builders

On-site engineering support

Real-time updates to reflect field changes

EPLAN eVIEW and Smart Wiring implementation

Commissioning assistance and verification

Business Benefits of EPLAN-Based Design

Reduced Engineering Time: EPLAN’s automation capabilities allow us to complete designs faster than traditional methods. Routine tasks like drawing connections, generating reports, or renumbering components are automated, freeing up engineering time for value-added activities.

For our clients, this means lower engineering costs and faster time-to-market for your automation projects.

Superior Documentation: Every wire, terminal, and component is clearly identified and cross-referenced in EPLAN projects. This high-quality, standardised documentation makes maintenance and troubleshooting significantly easier throughout your system’s lifetime.

When issues arise, maintenance technicians can quickly navigate drawings, trace circuits, and locate components, reducing downtime and repair costs.

Fewer Commissioning Errors: With thorough EPLAN design, assembly and wiring tend to be correct the first time. Potential errors are eliminated at the design stage – EPLAN’s 3D panel layout catches space issues, and electrical rule-checks identify connection problems before building begins.

The result is smoother commissioning with fewer surprises, delays, or costly rework.

Future Scalability: A well-structured EPLAN design sets you up for easier expansion later. Our modular approach creates reusable circuit macros for common functions that can be quickly adapted for system expansions or new projects.Even years later, new equipment can follow the same structured standards integrate with your existing documentation.

Why Choose EPLAN Over Other CAD Tools?

Purpose-Built for Automation

Unlike general CAD programs, which are essentially electronic drawing boards, EPLAN is specifically designed for electrical engineering tasks. It treats the electrical project as a connected whole, not just a collection of separate drawings.

This database-driven approach ensures all project information is stored centrally and consistently, with changes propagating automatically across the entire project.

Integration from Schematics to 3D Panel

A standout feature of EPLAN is its Pro Panel module, which brings 3D modeling directly into the electrical design process. The same software that creates your schematic also produces a 3D layout of your control cabinet.

This integration yields multiple advantages: accurate wire length calculations, automated drilling templates, collision checks, and visualisation capabilities that bridge the gap between design and manufacturing.

Our End-to-End Design Process

1. Concept Development & Pre-Planning

We work with you to define requirements and initial system architecture. Using EPLAN Preplanning, we capture engineering data such as basic function diagrams or plant overview drawings to establish project scope and generate initial specifications.

2. Detailed Schematic Design

Our engineers develop comprehensive electrical schematics using EPLAN Electric P8, including multi-line wiring diagrams, control circuit schematics, PLC I/O drawings, and power distribution drawings. Every device is placed with manufacturer-specific data, and all connections are precisely defined.

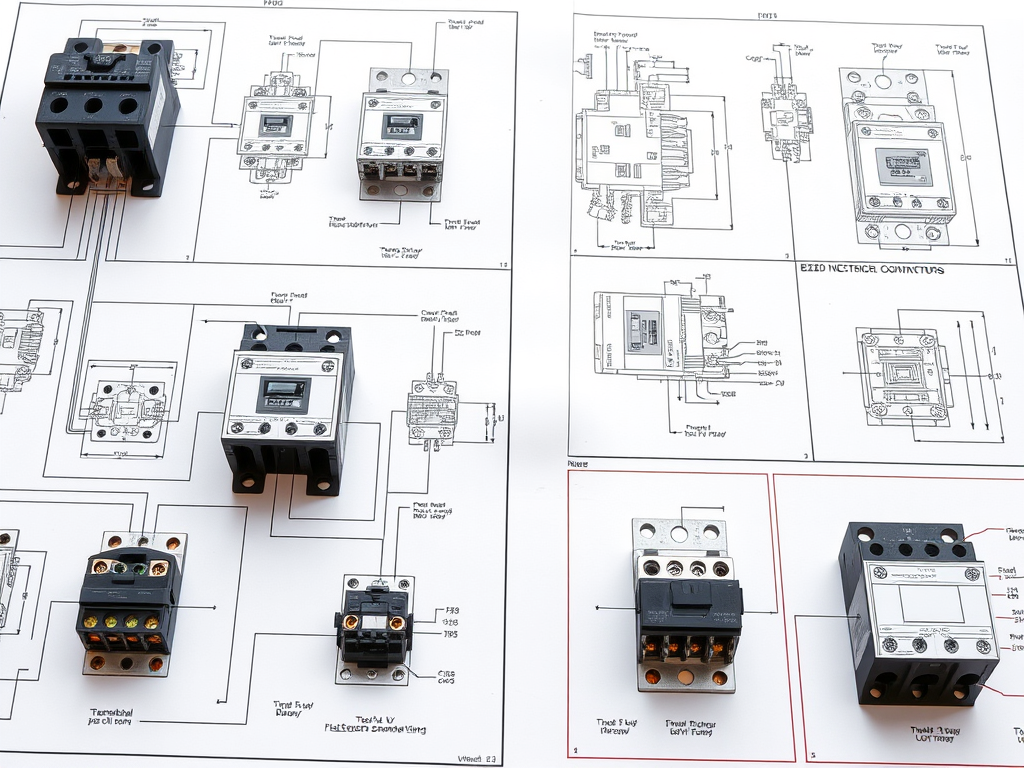

3. Component Selection & Parts Integration

We handle component selection according to your specifications, leveraging EPLAN’s vast component database with technical data, symbols, and 3D models. Each component in the drawings is linked to a part number and data sheet, ensuring accuracy in the Bill of Materials.

4. Wiring Diagrams & Terminal Plans

With the schematics in place, we refine EPLAN’s automatically generated connection lists into clear wiring diagrams and terminal connection plans. Every wire is numbered, and terminal strips are detailed showing precise connections for installation teams.

5. Control Panel Layout & Enclosure Design

Using EPLAN Pro Panel, we create a digital twin of your control cabinet with all devices positioned on DIN rails or backplates and all wiring routes planned. This 3D model ensures proper spacing, checks clearances, and identifies any physical interference issues before fabrication.

6. Bill of Materials & Procurement Data

We generate accurate Bills of Materials directly from the EPLAN project, providing a structured parts list organised by categories for simplified ordering. Additional outputs include wiring lists, cable schedules, and panel drawings to support procurement and manufacturing.

7. Installation, Testing & Documentation

Our support continues through installation and commissioning with detailed documentation for assembly and wiring. During on-site work, we make any necessary adjustments and deliver final as-built drawings that reflect the installed system for future reference.

Why Choose Sull Systems?

Our engineers are certified in EPLAN Electric P8 and Pro Panel, ensuring your electrical designs are accurate, clear, and automation-ready.

We take projects from concept to completion, providing everything from 2D schematics and wiring diagrams to 3D panel layouts and bill of materials.

All drawings are created to meet industry standards such as IEC, CE marking, and best practices for panel building.

Components are selected using EPLAN’s live database, ensuring that each part includes the correct part number, datasheet, and physical footprint.

Our documentation is structured to support collaboration between your engineers, installation teams, and panel builders.

Whether you’re developing one control panel or a full suite of designs for multiple facilities, our scalable approach ensures consistency and growth.