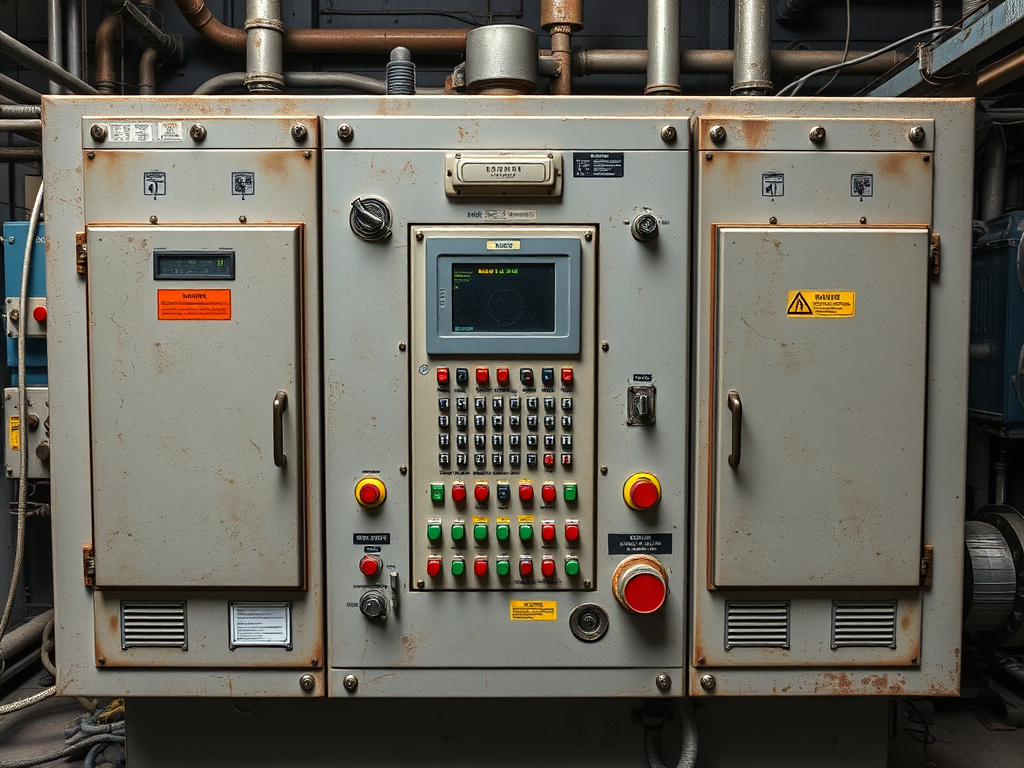

Modernising Legacy Control Panels

Many production plants still rely on decades-old PLCs and control panels. These legacy systems suffer from obsolete hardware, poor diagnostics, and reduced processing power. At Sull Systems, we specialise in modernising these aging systems to ensure your facility maintains peak performance and reliability.

Legacy System Challenges

Reduced processing power and integration capabilities

Harder to find spare parts and support

Primary cause of control-system failures

Shrinking pool of engineers familiar with old platforms

Lack of modern diagnostics and data connectivity

No vendor support for obsolete devices

Benefits of Control System Modernisation

Upgrading legacy control systems delivers substantial operational advantages. Modern controllers offer enhanced diagnostics and processing speeds, while providing data visibility that prevents costly breakdowns. New PLCs reduce energy consumption through intelligent power management. Updated systems simplify regulatory compliance and eliminate the maintenance burden of obsolete parts, freeing your team to focus on genuine improvements rather than keeping outdated systems operational.

Performance

Swap old PLCs with modern equivalents while preserving existing program logic structure using migration tools.

Energy Montoring

Utilise retrofit kits to maintain existing field wiring while upgrading to new I/O cards for cost efficiency.

Visibility

Convert to new controller families (e.g., SLC-500 to ControlLogix, S7-300 to S7-1500) with automated code conversion.

Regulatory Compliance

Combine old and new equipment for phased migration, moving critical loops first while keeping production running.

Straightforward Maintenance

Current-generation PLCs come with proper technical support and readily available spare parts, freeing your engineers from hunting for obsolete components and letting them focus on meaningful improvements.

Retrofit Strategies

Like-for-Like Upgrades

Swap old PLCs with modern equivalents while preserving existing program logic structure using migration tools.

I/O Preservation

Utilise retrofit kits to maintain existing field wiring while upgrading to new I/O cards for cost efficiency.

Platform Migration

Convert to new controller families (e.g., SLC-500 to ControlLogix, S7-300 to S7-1500) with automated code conversion.

Hybrid Approach

Combine old and new equipment for phased migration, moving critical loops first while keeping production running.

Engineering Workflow

1

Pre-Assessment

Review historical data and operating conditions

2

Baseline Testing

Initial measurements of all critical parameters

3

Thermal Imaging

Detailed infrared scanning of entire panel

4

Intrusive Testing

Component-level evaluation and testing

5

Risk Analysis

Failure probability and impact assessment

6

Strategy Development

Maintenance and modernisation planning

Control Panel Upgrade Tasks?

I/O & PLC Modules

Swap old rack I/O systems with new modules, introduce remote I/O networks to reduce wiring, and verify all digital/analog points.

Network Infrastructure

Replace legacy serial links with industrial Ethernet/fiber optics and install new switches for modern communications.

Power Systems

Replace aging power supplies with high-efficiency models and upgrade cooling systems with proper thermal management for modern LED/electronic components.

Safety Systems

Add safety relays, dedicated safety I/O modules, and emergency stops/interlocks with proper certification for regulatory compliance.

Our Downtime Reduction Strategy

We understand that downtime is the enemy of any retrofit project. Our approach includes:

- Parallel Builds: New panels fabricated off-site allowing continuous plant operation

- Staged Cutovers: Systems upgraded incrementally over planned maintenance windows

- Hot Cutover Methods: Running new/old controls in parallel on separate channels

- Thorough Pre-testing: All hardware and software pre-verified in FAT environment

- Minute-by-Minute Planning: Choreographed changeovers procedures with rehearsed tasks

Recent project success: Over 800 I/O points cut over during a single weekend with zero unplanned downtime.

Real-World Success Stories

Pharmaceutical Plant Modernisation

Pharmaceuticals upgraded their entire 1985-era control system to modern PlantPAx/DCS platform. The project included rewriting all PLC code and replacing analog loop controllers in just five weeks of planned downtime.

Results:

First-time daily production reporting

Historical data for predictive maintenance

Remote diagnostic capability

Faster fault recovery through better parts availability

Dramatically improved uptime without new plant construction.

Food Processing Success

Snack manufacturer needed to triple throughput. New Siemens S7-1500 PLC and PROFINET network installation replaced legacy PLCs.

Achievements:

Improved process consistency and higher yield

50% capacity increase

Unified control system with recipe management

Minimal downtime with phased upgrade approach

On-time project delivery despite performance boost

Quantifiable Benefits

Performance Improvements:

Higher processing speed enables tighter control loops

Reduced unplanned downtime

Fewer component breakdowns

Significant energy savings (up to 12-18%)

Operational Enhancements:

Shift from reactive to predictive maintenance

Better data visibility for analytics

Improved regulatory compliance

Simpler staffing with active vendor support

Why Choose Sull Systems?

Comprehensive Assessment: Complete site surveys and I/O mapping with detailed upgrade planning to ensure nothing is overlooked.

Off-site FAT Testing: Build and test new panels in our workshop, verifying all systems before site arrival.

Scheduled Coordination: Work within your production schedule for minimal disruption using parallel-run strategies.

Turnkey Solution: Handle everything from panel wiring and PLC programming to HMI migration and training.

Proven Results: Successfully migrated 800+ I/O channels over single weekends without unplanned downtime.

Future-Ready Solutions: Deliver systems with faster processors, full data connectivity, and ongoing vendor support