Solutions Safe, Modern Automation for Critical Processes

Oil and gas operations require automation solutions that prioritise safety whilst delivering reliable performance in challenging environments. We specialise in safety instrumented systems (SIS) that meet the stringent requirements of IEC 61511, ensuring your operations protect personnel, environment, and assets.

Our Control & Automation Expertise

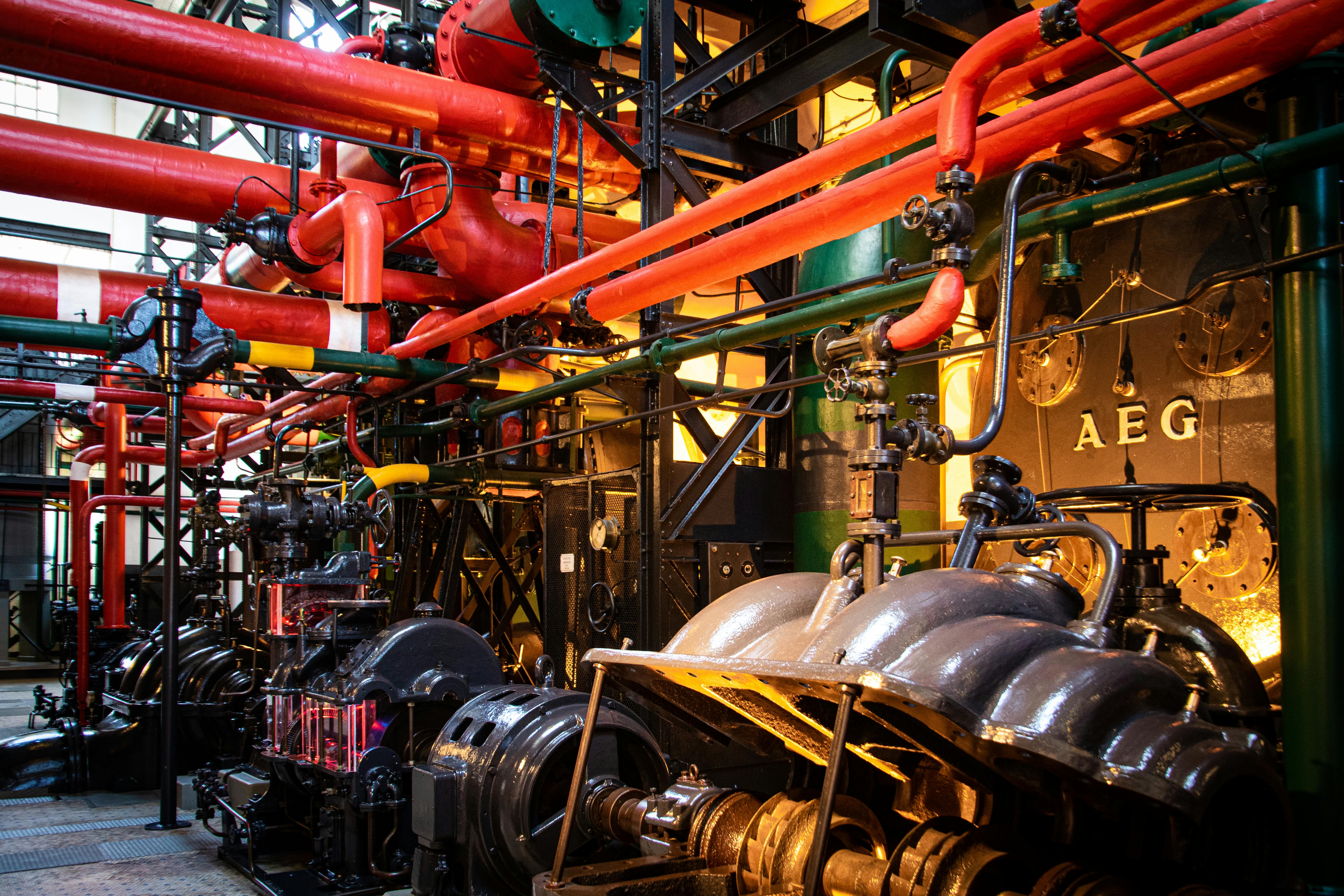

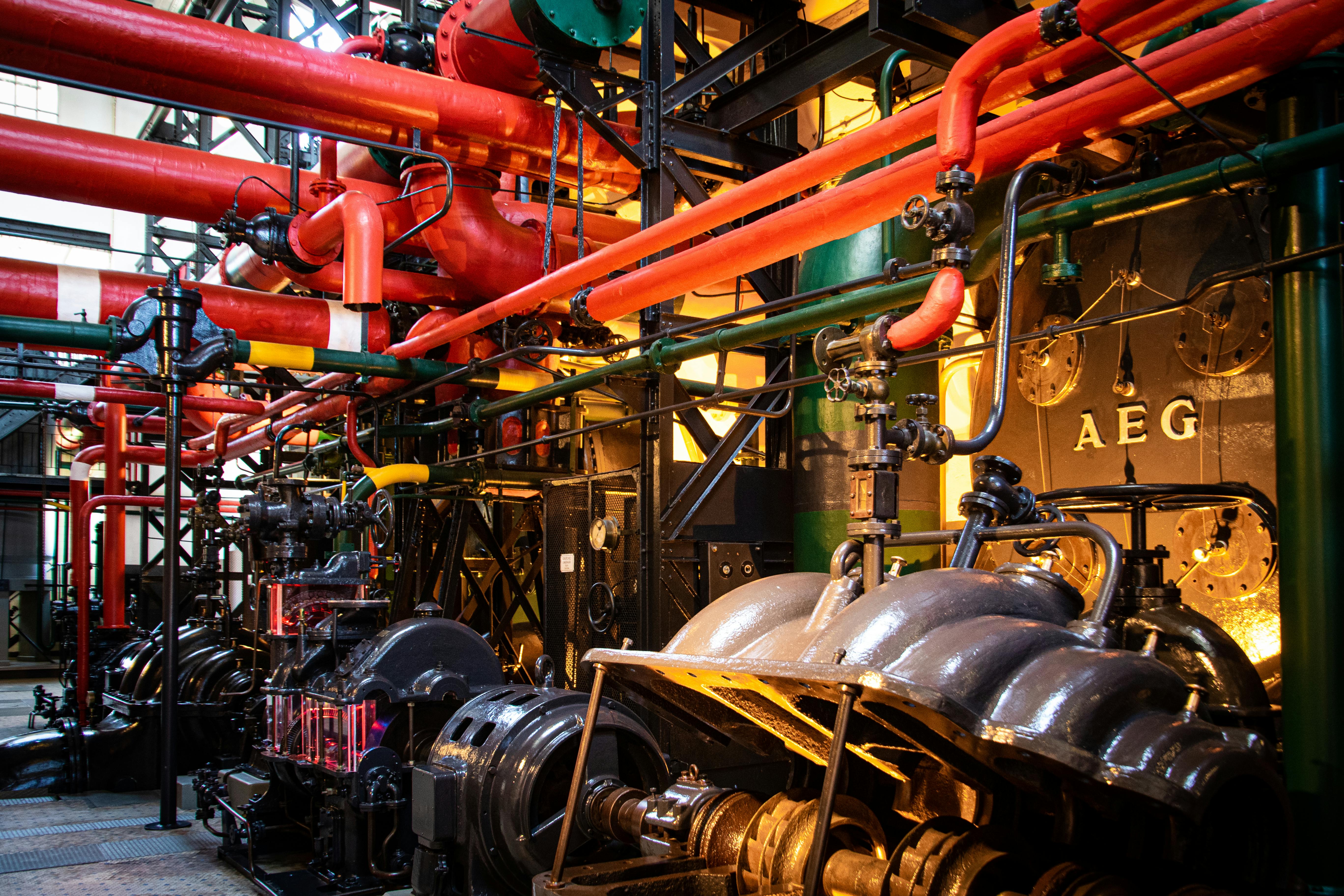

Safety-Critical Control Systems

Our control and automation solutions are designed specifically for the demanding requirements of oil and gas operations, where safety cannot be compromised and reliability is essential for continuous operation.

Our Expertise Includes:

Safety Instrumented Systems (SIS) certified up to SIL 3 for critical safety functions

Fire and gas detection systems with integrated emergency shutdown capabilities

Hazardous area control systems meeting ATEX and IECEx standards

Remote monitoring and SCADA systems for unmanned installations

Pipeline pressure and flow control systems

Emergency shutdown and blowdown systems with proven reliability

Process Control Applications

Wellsite Control Systems:

Automated control of pumps, wellheads, and blowout preventers

Remote valve control with automatic shutdown protocols

Real-time monitoring of well pressure and drilling parameters

Pipeline Control & Monitoring:

Pressure transmitters and flow metres feeding central SCADA systems

Automated isolation valves enabling immediate shut-off on leak detection

Continuous pipeline flow and pressure monitoring to detect anomalies

Processing Plant Automation:

PLC/DCS control of separators, compressors, and utilities

Explosion-proof control systems for hazardous environments

Integrated emergency shutdown (ESD) panels for critical conditions

Remote Monitoring Solutions

SCADA and distributed control systems gather real-time data from wells, pipelines, and processing units, providing 24/7 oversight of field assets. Our systems enable:

Automated Response: Immediate isolation and shutdown capabilities for emergency conditions

Centralised Control: Monitor and control distributed assets from central control rooms

Predictive Analytics: Early detection of equipment anomalies and process deviations

Common Challenges We Address

Ageing Safety Systems

Legacy safety instrumentation that no longer meets current IEC 61511 standards, requiring modernisation without disrupting ongoing operations.

Integration Complexity

Connecting new safety systems with existing process control infrastructure whilst maintaining complete functional separation.

Cybersecurity Vulnerabilities

Protecting critical safety systems from cyber threats whilst enabling necessary data communication and remote monitoring

High Maintenance Costs

Reducing operational expenses through modern, reliable control systems that require less frequent intervention.

Regulatory Compliance

Ensuring control systems meet evolving safety regulations and standards across different operational jurisdictions.

Hazardous Environment Challenges

Implementing control solutions that operate reliably in explosive atmospheres and extreme conditions.

The Benefits of Modern Control Systems

Enhanced Safety Performance

SIL-rated safety systems provide proven protection for personnel, environment, and assets with mathematically quantified reliability.

Improved Operational Efficiency

Integrated systems coordinate ingredient dosing, mixing, and cooking processes with precise timing and temperature control

Reduced Operational Costs

Automated conveyor lines and robotic sorters move products with speed and accuracy, reducing manual handling and improving throughput

Regulatory Compliance

Systems designed to meet current and evolving safety standards, ensuring long-term compliance without frequent upgrades.

Cybersecurity Protection

Air-gapped safety systems and secure communication protocols protect critical infrastructure from cyber threats.

Remote Operation Capability

SCADA and telemetry systems enable safe, efficient operation of unmanned installations.

Ready to Discuss Your Requirements?

Oil and gas operations face unique automation challenges that require specialist knowledge and proven experience. Whether you’re modernising existing safety systems, implementing new control infrastructure, or addressing cybersecurity concerns, we understand the critical nature of your operations.

Contact us today to discuss how our control and automation expertise can enhance the safety and efficiency of your oil and gas operations.